Quality Control

Every product from Wosente is 100% strictly tested.

Total Quality Control Standard

Brand new

Replace the cover plate

Original raw materials, replacement parts, 2 refurbishments,After 44 rounds of installation testing,Aging test experiment,Display and brightness comparison,72 hour high refresh rate test.

OEM

The original configuration was processed by a third-party factory;After 44 rounds of installation testing;Aging test experiment;Display and brightness comparison;72 hour high refresh rate test.

OLED

Change plan for large factory glass and glass of the same size specifications;After 44 rounds of installation testing;Aging test experiment Display and brightness comparison;72 hour high refresh rate test.

INCELL

Change plan for domestic glass+integrated process;After 44 rounds of installation testing;Display and brightness comparison;72 hour high refresh rate test.

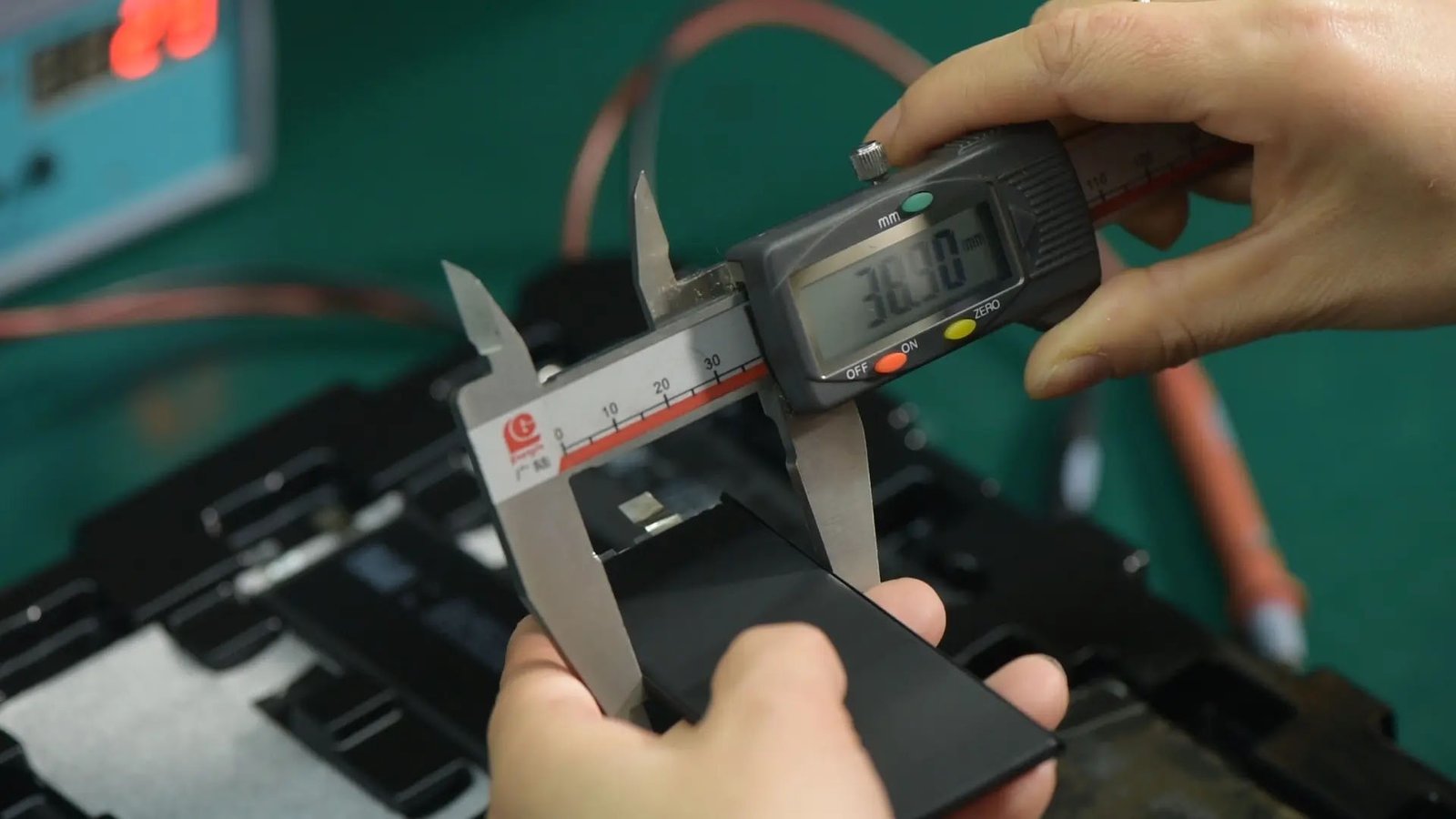

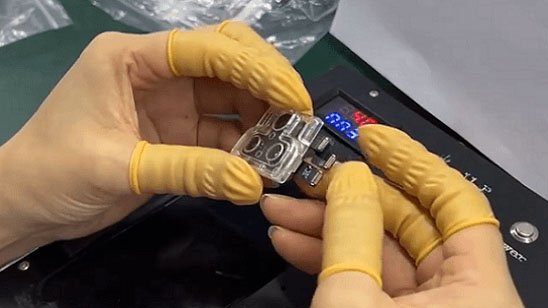

Total Quality Control Process

We ensure that every product meets the high standards you expect. Our quality control process involves comprehensive inspections and assessments, so you can feel confident in every purchase.

Step 1: Factory delivery

Step 2: Laboratory appearance screening

Step 3: Comparison of the first brightness and resolution of the goods to record data

Step 4: Installed game and APP detection record data

Step 5: Brightness adjustment detection

Step 6: 26 keyboard and call key detection

Step 7: Perform 72-hour video flash detection

Step 8: Full screen 3-finger touch detection

Step 9: Lock screen open and switch on and off repeatedly

Step 10: Update system version detection

Step 11: Enter the warehouse inventory

Step 12: Perform the second appearance and function detection

Step 13: Assembly frame

Step 14: Perform the last function check

Step 15: Assembly line injection film replacement packaging

Step 16: Packaging compression test

Step 17: Deliver to customers

- Screen

- Battery

- Small Parts

Certified Globally

IEC62133 | CE | FCC | RoHS | MSDS | UN38.3 | SDS